Digital Twins: Boost Business with Virtual Replicas

Businesses of all sizes are constantly seeking innovative technologies to optimize operations, enhance decision-making, and drive competitive advantage. Enter digital twins, a transformative concept that bridges the physical and virtual realms, enabling organizations to create dynamic, real-time virtual replicas of physical assets, processes, or systems. This article explores how digital twins are revolutionizing industries, their technical underpinnings, business applications, and strategies for successful implementation, all while offering actionable insights for IT and business decision-makers.

What Are Digital Twins?

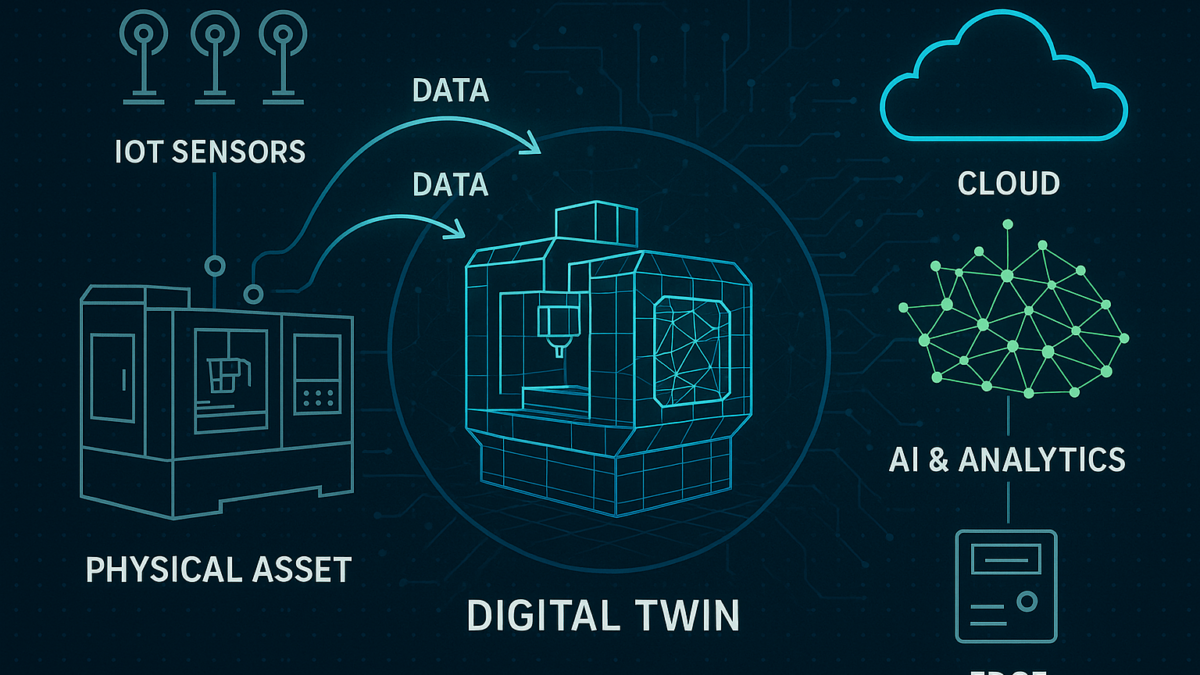

A digital twin is a virtual model of a physical entity—be it a machine, building, supply chain, or even an entire city—that mirrors its real-world counterpart in real time. Powered by Internet of Things (IoT) sensors, artificial intelligence (AI), machine learning (ML), and big data analytics, digital twins provide a dynamic, data-rich representation that evolves alongside the physical asset. Unlike static simulations, digital twins are continuously updated with real-time data, enabling predictive insights, performance optimization, and scenario testing.

Key Characteristics of Digital Twins

- Real-Time Data Integration: IoT sensors collect data from physical assets, feeding it into the digital twin for live updates.

- Bidirectional Connectivity: Digital twins can influence physical systems, enabling adjustments based on virtual simulations.

- Scalability: Applicable to individual components (e.g., a turbine blade) or complex systems (e.g., a smart city).

- Predictive Capabilities: AI and ML analyze historical and real-time data to forecast outcomes and identify anomalies.

By leveraging these characteristics, digital twins empower businesses to optimize operations, reduce costs, and accelerate innovation.

The Technical Foundations of Digital Twins

To fully appreciate the transformative potential of digital twins, IT decision-makers must understand their technical architecture. Digital twins rely on a sophisticated ecosystem of technologies working in concert.

- IoT and Sensor Networks

IoT devices form the backbone of digital twins by collecting real-time data from physical assets. Sensors monitor variables such as temperature, pressure, vibration, and location, transmitting data to the digital twin via secure cloud or edge computing platforms. For example, in manufacturing, sensors on a production line track equipment performance, feeding data to a digital twin for predictive maintenance.

- Cloud and Edge Computing

Cloud platforms provide the computational power and storage needed to process vast amounts of IoT data, while edge computing enables low-latency processing closer to the data source. Hybrid architectures combining cloud and edge are increasingly common, ensuring scalability and responsiveness for digital twin applications.

- AI and Machine Learning

AI and ML algorithms analyze data from digital twins to uncover patterns, predict failures, and optimize performance. For instance, a digital twin of a wind turbine can use ML to predict blade wear, recommending maintenance before a failure occurs. Advanced techniques like deep learning enhance the accuracy of these predictions.

- 3D Modeling and Visualization

Digital twins often incorporate 3D models to provide a visual representation of physical assets. Tools like Building Information Modeling (BIM) in construction or Computer-Aided Design (CAD) in manufacturing enable precise virtual replicas. Augmented reality (AR) and virtual reality (VR) further enhance visualization, allowing stakeholders to interact with digital twins in immersive environments.

- Cybersecurity and Data Governance

Given the sensitive nature of IoT data, robust cybersecurity measures are critical. Encryption, secure APIs, and zero-trust architectures protect digital twins from cyber threats. Additionally, data governance frameworks ensure compliance with regulations like GDPR or CCPA, safeguarding customer trust.

Business Applications of Digital Twins

Business Applications of Digital Twins

Digital twins are reshaping industries by enabling data-driven decision-making, operational efficiency, and innovation. Below are key applications across sectors, tailored to the interests of business and IT leaders.

- Manufacturing: Predictive Maintenance and Smart Factories

In manufacturing, digital twins optimize production lines and reduce downtime. A digital twin of a factory machine can monitor performance metrics, predict failures, and schedule maintenance proactively. According to a Deloitte study, predictive maintenance powered by digital twins can reduce maintenance costs by up to 40% and increase equipment uptime by 20%.

Case Study: Siemens Siemens uses digital twins to optimize gas turbine production. By creating virtual replicas of turbines, Siemens simulates performance under various conditions, reducing design cycles by 30% and improving energy efficiency.

- Healthcare: Personalized Medicine and Facility Management

In healthcare, digital twins of patients—built from medical imaging, wearables, and genomic data—enable personalized treatment plans. For example, a digital twin of a heart can simulate responses to medications, aiding cardiologists in selecting optimal therapies. Additionally, digital twins of hospitals optimize resource allocation, from bed management to HVAC systems.

Case Study: Philips Philips leverages digital twins to enhance medical imaging systems, using real-time data to improve diagnostic accuracy and reduce equipment downtime.

- Smart Cities: Urban Planning and Sustainability

Digital twins of cities, like Singapore’s Virtual Singapore platform, model infrastructure, traffic, and energy usage. Urban planners use these twins to simulate the impact of new developments, optimize traffic flow, and reduce carbon emissions. For business leaders, smart city digital twins open opportunities in real estate, transportation, and utilities.

- Supply Chain: Resilience and Optimization

Digital twins of supply chains provide end-to-end visibility, enabling businesses to mitigate disruptions. By modeling suppliers, warehouses, and logistics, companies can simulate scenarios like port delays or demand spikes. A Gartner report predicts that by 2026, 80% of global enterprises will use digital twins for supply chain optimization.

Case Study: DHL DHL employs digital twins to optimize warehouse operations, reducing delivery times by 15% through real-time inventory tracking and route optimization.

- Energy: Renewable Integration and Grid Management

In the energy sector, digital twins of wind farms, solar panels, or power grids enhance efficiency and reliability. For example, a digital twin of a wind farm can optimize turbine placement to maximize energy output while minimizing maintenance costs.

Business Benefits of Digital Twins

For C-suite executives and IT leaders, digital twins deliver measurable value across multiple dimensions.

- Cost Reduction

By predicting maintenance needs and optimizing processes, digital twins reduce operational costs. A McKinsey report estimates that digital twins can lower manufacturing costs by 10-20%.

- Enhanced Decision-Making

Real-time insights from digital twins enable data-driven decisions. For instance, a retailer using a digital twin of its supply chain can adjust inventory levels based on predictive demand models.

- Accelerated Innovation

Digital twins allow businesses to test new products or processes virtually, reducing time-to-market. In aerospace, companies like Boeing use digital twins to simulate aircraft designs, cutting development time by up to 50%.

- Sustainability

By optimizing energy usage and reducing waste, digital twins support corporate sustainability goals. For example, a digital twin of a building can adjust HVAC systems to minimize energy consumption, aligning with net-zero targets.

- Customer Satisfaction

Improved product quality and faster delivery times—enabled by digital twins—enhance customer experiences. In automotive, digital twins ensure vehicles meet performance standards before production, reducing recalls.

Challenges and Considerations for Implementation

While digital twins offer immense potential, their adoption comes with challenges that IT and business leaders must address.

- Data Integration and Quality

Digital twins rely on high-quality, interoperable data from diverse sources. Legacy systems and siloed data can hinder integration. Solution: Invest in data lakes and middleware to unify data streams.

- Scalability

Scaling digital twins from a single asset to an enterprise-wide system requires robust infrastructure. Cloud platforms like AWS IoT TwinMaker or Microsoft Azure Digital Twins can simplify scaling.

- Cybersecurity Risks

The connectivity of digital twins increases exposure to cyber threats. Solution: Implement end-to-end encryption and regular security audits.

- Skill Gaps

Building and managing digital twins requires expertise in IoT, AI, and data science. Solution: Partner with technology providers or upskill internal teams through training programs.

- Cost of Implementation

Initial costs for IoT infrastructure and software can be significant. Solution: Start with pilot projects to demonstrate ROI before scaling.

Strategies for Successful Digital Twin Adoption

To maximize the value of digital twins, organizations should adopt a strategic approach.

- Define Clear Objectives

Align digital twin initiatives with business goals, such as cost reduction or product innovation. For example, a manufacturer might prioritize predictive maintenance to reduce downtime.

- Start Small, Scale Fast

Begin with a single use case, such as a digital twin of a critical machine, to validate the technology. Use lessons learned to scale across the organization.

- Partner with Technology Providers

Collaborate with vendors like GE Digital, IBM, or PTC, which offer mature digital twin platforms. These partners can accelerate deployment and provide ongoing support. AI consultants, like Macronet Services, can guide you to the best resources for your objectives.

- Foster Cross-Functional Collaboration

Digital twins require input from IT, operations, and business units. Establish cross-functional teams to ensure alignment and drive adoption.

- Measure and Optimize

Track KPIs like cost savings, uptime, or time-to-market to quantify the impact of digital twins. Use these insights to refine models and processes.

The Future of Digital Twins

As technologies evolve, digital twins will become even more powerful. Emerging trends include:

- AI-Driven Autonomy: Advanced AI will enable digital twins to make autonomous decisions, such as adjusting production schedules without human intervention.

- Metaverse Integration: Digital twins will integrate with metaverse environments, creating immersive simulations for training or product design.

- Quantum Computing: Quantum-powered digital twins will handle complex simulations, such as modeling entire ecosystems, with unprecedented speed.

- Industry Standards: Efforts like the Digital Twin Consortium are developing interoperability standards, fostering broader adoption.

By 2030, IDC predicts the digital twin market will reach $183 billion, driven by demand for real-time insights and operational efficiency.

Conclusion: Embrace the Digital Twin Revolution

Digital twins are no longer a futuristic concept—they are a strategic imperative for businesses seeking to thrive in a competitive landscape. By creating virtual replicas of physical assets, organizations can unlock unprecedented levels of efficiency, innovation, and sustainability. For IT and business decision-makers, the path forward involves understanding the technical foundations, aligning digital twin initiatives with business goals, and overcoming implementation challenges through strategic planning.

Ready to revolutionize your business with digital twins? Start by assessing your organization’s data readiness and identifying high-impact use cases. Partner with technology providers to build a roadmap for adoption, and position your business at the forefront of the digital twin revolution. Please don’t hesitate to reach out to us to discuss your objectives and to learn about how we can help.

Tags In

Related Posts

Recent Posts

- Tier 1 vs Tier 2 vs Tier 3 ISPs Explained: The Complete Guide for IT Leaders

- America’s AI Action Plan 2025: What CEOs, CIOs, and CFOs Need to Know

- The AIoT Advantage: Harnessing the Convergence of Artificial Intelligence and the Internet of Things

- Quack AI Governance in the Age of Algorithmic Hype

- NVIDIA Corporation: A Strategic Analysis for Business Executives Navigating the AI Ecosystem

Archives

- August 2025

- July 2025

- June 2025

- May 2025

- April 2025

- March 2025

- February 2025

- January 2025

- December 2024

- November 2024

- October 2024

- September 2024

- August 2024

- July 2024

- June 2024

- May 2024

- April 2024

- March 2024

- February 2024

- January 2024

- December 2023

- November 2023

- October 2023

- September 2023

- August 2023

- July 2023

- June 2023

- May 2023

- April 2023

- March 2023

- February 2023

- January 2023

- December 2022

- November 2022

- October 2022

- September 2022

- August 2022

- July 2022

- June 2022

- May 2022

- April 2022

- March 2022

- February 2022

- January 2022

- December 2021

- November 2021

- October 2021

- September 2021

- August 2021

- July 2021

- June 2021

- May 2021

- April 2021

- March 2021

- December 2020

- September 2020

- August 2020

- July 2020

- June 2020

Categories

- All (19)

- Satellite (1)

- Artificial Intelligence (7)

- Travel (1)

- Sports (1)

- Music (1)

- News (275)

- Design (3)

- Clients (12)

- Uncategorized (1)

- Tips & tricks (25)

- Inspiration (9)

- Client story (1)

- Unified Communications (196)

- Wide Area Network (309)

- Cloud SaaS (60)

- Security Services (71)